Industry Activities

A-KRAFT TOOLS, Ratchet-KH3200S New Choice for Narrow Space Fastening

Add to my favorite

2022-05-31

A-KRAFT TOOLS MANUFACTURING CO., LTD.

Ratchet-KH3200S New Choice for Narrow Space Fastening

The problem of traditional ratchet wrenches being difficult for fastening operation in narrow space has always troubled many users. Not to mention the gradual electronization and automation developed in mechanical-related industries, as well as the design of electric vehicles, the development makes the space for follow-up maintenance and repairs of certain mechanisms more limited. Thus, A-KRAFT Tools Manufacturing Co., Ltd. developed the Ratchet-KH3200S ratchet wrench. Not only can it fully meet the growing demands of the professional tool market, but also completely solves the problems that traditional ratchet wrenches are too long and heavy to use. At present, 80% of Ratchet-KH3200S are being sold to Europe, and they have successfully entered the professional auto repair and construction hardware markets.

120 Ratchet Teeth + Light Weight

Suitable for Narrow Space Fastening

The operating angle of the traditional ratchet is generally 15 degrees and the tool often needs more space for operation. To maximize the effectiveness of the actual operation of the product, Ratchet-KH3200S has ratchet teeth up to 120, which can greatly reduce the space required for the operation of the ratchet structure and decrease the operating angle to 3 degrees. Users can easily complete the fastening operation even when they are in narrow space. Besides, A-KRAFT Tools R&D teams also reduced the weight of products to make more efficient use of space. They reduced the width and thickness of the ratchet wrench by 30% to meet customers' needs for lightweight tools. Currently, there are four specifications available, which include “1/4” DR., 3/8” DR., 1/2” DR., and 1/4” Hex,” and the company can provide various and customized packages according to different markets and customer needs.

Ergonomic Handle for Easier Operation

Efficiency Better Than International Standard with High Stability

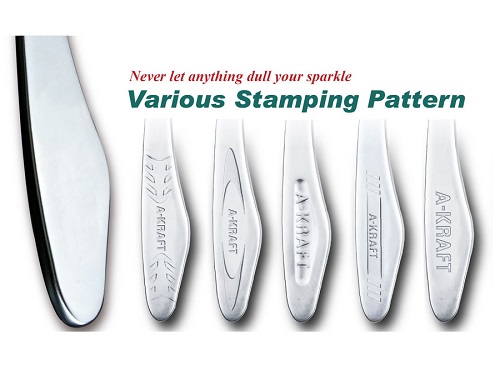

The irregular arc handle of the Ratchet-KH3200S has undergone many practical tests, drawing, modification, 3D printing... and factors such as force, comfort, tool weight and working environment have been fully considered to create the most ergonomic design. It makes the operation more energy-saving and convenient, and also greatly optimizes and improves the work efficiency. The handle can also be customized with trademarks or directly molded logos in accordance with customer needs to enhance customers’ brand awareness and market recognition. Now Ratchet-KH3200S has obtained design patents in Taiwan and Germany, and the company is also planning to apply for EU and American patents in the future. In terms of product torque, the performance of Ratchet-KH3200S is also significantly better than market standards and international norms (e.g., DIN, ANSI, JIS, etc.), and the surface of the product has been also done with the best anti-wear and anti-rust special electroplating treatment to extend its service life. Through the optimization of the production, the cost and defect rate are also greatly reduced, and the stability is also significantly improved.

A-KRAFT Tools said, “In September and October of this year, we plan to participate in the International Hardware Fair Cologne (IHF), Automechanika Frankfurt, and Taiwan International Tools & Hardware Expo to fully demonstrate the advantages of Ratchet-KH3200S, strengthen market promotion and provide customers with the whole new experience of ratchet products. We are very confident that we can get the affirmation and recognition from customers and the market.”

Contact: Mr. Jeff Chen (Vice General Manager)

Email: 0358@akraft.com.tw

A-KRAFT TOOLS MANUFACTURING CO.

LTD.

Ratchet-KH3200S

New Choice

Narrow

Space

Fastening

磯慶實業

狹小空間

鎖固

扣件

國際展會

惠達雜誌

匯達實業

外銷媒合

廣告刊登

螺絲五金

五金工具

紧固件

台灣扣件展

印度新德里螺絲展

越南河內螺絲展

墨西哥瓜達拉哈拉螺絲展

美國拉斯維加斯螺絲暨機械設備展

波蘭克拉科夫螺絲展

義大利米蘭螺絲展

德國司徒加特螺絲展

wire Dusseldorf

FASTENER FAIR INDIA

FASTENER FAIR VIETNAM

FASTENER FAIR MEXICO

FASTENER POLAND

FASTENER FAIR ITALY

FASTENER FAIR GLOBAL

FASTENER WORLD

READ NEXT

Subscribe