Industry Activities

Congrats on Successful 2024 Product Launch of Ching Chan Optical Technology (CCM)! Special Interview with General Manager Thomas Chou

Add to my favorite

2024-11-20

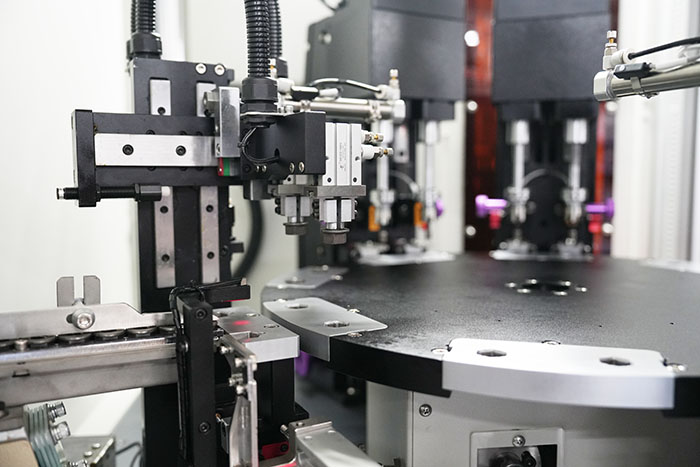

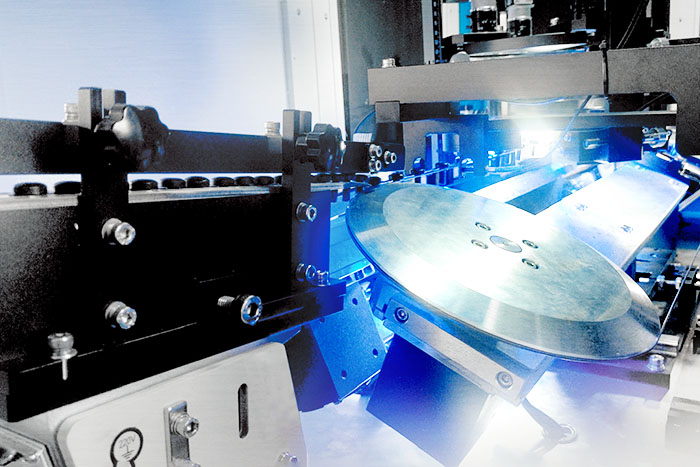

On October 25, once again CCM showcased to the world its new evolution in optical inspection, adding new technology to the current sorting machines and displaying all-new machines. The launch event featured an incorporation of conventional AOI (Automated Optical Inspection), AI (Artificial Intelligence) and AXI (Automated X-ray Inspection), with applications extending beyond fasteners and hardware components to electronics, semiconductor chips, and pharmaceutical tablets. Over 200 attendees witnessed live demonstrations of CCM's independently developed inspection software and its nearly 50 patented technologies.

Highlights of New Products:

☆ New High Performance Optical Sorting Machine:

Latest fly tracking system for multifunctional material and crack inspection in one go.

Automatic focus: One-click line change for faster inspection of objects in check.

Quality inspection machine on production line: Suitable for auto-focusing models, increasing demand for quality inspection.

☆ Glass Dial Sorting Machine: Enhanced with AI inspection capabilities to improve detection rates.

☆ Steel Wire Image Sorting Machine: Uses two wires to hang up screws for inspection.

☆ Go/No-Go Sorting Machine:

Go gauge: Inspects thread damage, drilling defect, and NG threading.

No-go gauge: Inspects over-drilling.

☆ Tablets Sorting Machine: The first of its kind in Taiwan, compliant with GMP regulations, used in pharmaceutical factories for two years. Suitable for uncoated tablets, film-coated tablets, and sugar-coated tablets, it offers a complete AOI + AI inspection solution with 360° full appearance inspection, providing robust equipment for the Contract Development and Manufacturing Organization industry chain.

☆ Chip-type Electronic Component Appearance Defect Inspection Machine: Conducts eight-sided appearance inspection with high compatibility and excellent inspection capabilities. Equipped with an auto-zoom lens for quick line changes and customizable inspection functions and area to meet small-volume, large-variety manufacturing needs.

☆ Process Monitoring: Offers 2 to 8 simulation channels for monitoring dies life, digitizing production capacity control with real-time monitoring, shutdown configuration and alerts.

☆ Centrifugal Feeder: Suitable for light and heavy industries such as fasteners, chemicals, pharmaceuticals, food, and construction materials. It is fast, electricity-saving, low-noise and doesn’t damage materials. Reduced product surface collisions and damage to coating, only one-tenth power consumption of conventional vibrating plates.

☆ Automatic Packing System: Integrates packaging with sorting machines, allowing direct packaging of post-sorted good products into boxes to enhance productivity.

In this event, Fastener World had a special interview with General Manager Thomas Chou to explore CCM's business philosophy in his eyes through a Q&A session.

(CCM General Manager Thomas Chou)

Q1: CCM is one of the top brands in the industry with international acclaim. What differentiates your products from competitors?

A: Firstly, our starting point and philosophy are to "understand customer needs and exceed expectations." CCM monitors everything from fastener manufacturing to finished product inspection, providing maximum added value for the fastener industry. Secondly, we aim to be partners with our customers rather than just equipment suppliers. Our contributable values include inspection machines for final products, providing solutions, and developing technology and equipment collaboratively with key customers. Our success is tied to our customers' success. Thirdly, we provide quick and complete technical support and after-sales service. Fourth, we continuously improve core capabilities to align with customer needs. From surface defects, cracks, material hardness to products’ materials and abnormalities, we offer various optical inspection machines using cameras, lasers, eddy currents, AI, and X-rays to help clients confirm product quality and increase competitiveness.

Q2: Where is your technology headed to?

A: Firstly, we establish a technical ecosystem with a complete supply chain incorporating leading global component suppliers and technical partners, providing complete solutions and equipment, and working with global key clients. Secondly, we make our sorting machines inspect faster, inspect more precise products with higher accuracy and precision. We are developing technology from the outside in because we emphasize partnership, prioritizing customer needs and expectations. Meanwhile, for requests on product reliability, through-scan internal imaging inspection will be a continuously growing demand. Therefore, CCM has established a product line and technical team of eddy current and X-ray sorting machines to help clients gain competence. Thirdly, leveraging 30 years of experience and know-how, CCM's advanced optical sorting machines not only serve the fastener industry but also enter potential industries such as semiconductors, EVs, automation, robots, medical applications, and food safety. This includes diving further in fasteners, machined parts, forged parts, electronic components, tablets, capsules, and food.

Q3: How do global customers evaluate CCM's equipment?

A: Production speed, inspection accuracy and equipment reliability, combined with high problem-solving capabilities and solutions, have earned us high praise from global customers. We are undoubtedly the best choice on fastener sorting machines worldwide. We don’t leave our machines unattended. Each one represents a customer’s capital expenditure, and the space it takes, its utilization rate, and efficiency directly impact the customer's costs and competitiveness. We don’t want our machines left idle in customers' factories or production lines, so we are committed to after-sales and technical services to ensure the machines operate normally, allowing customers to use them with confidence. Our machines establish inspection data for every batch and every screw. It’s like each screw has its own quality ID. This effectively addresses defect rates and avoids trade disputes, resulting in considerable savings in gross margins and generated production value. Customers can use the data obtained from sorting as a basis for process improvement to maximize benefits. Additionally, our machines can display power and gas consumption data, allowing customers to convert this into carbon emissions data, providing support for their CBAM reporting.

Q4. What is your view on the industry's economic climate? Could you share your sales performance and overseas expansion status?

A: We know that due to geopolitical issues, wars, and the U.S. election, the fastener industry’s business model and production locations must adapt accordingly and meet the challenges of a post-globalization era characterized by global fragmentation. As the saying goes, "Different places can experience different weather." Customers’ development varies across different regions and industries. Our global deployment in Europe, America, Japan, China, Taiwan, and India offsets changes in individual regions. In response to global customers' need for risk-hedging, the fastener industry is expanding production to Southeast Asia and India. To seize this trend and provide local real-time service, we are actively seeking factory locations in Northern Vietnam and training sales, service, and technical personnel to serve customers and expand markets. With customers’ higher requirements (0 PPM) on product inspections, we’re compliant with IATF16949. Sorting machines are no longer optional but essential investments and tools for fastener manufacturers. We can assist customers in securing orders and meeting quality requirements.

Q5. Last year's launch received enthusiastic feedback. What were your goals for this year's event?

A: We uphold our root of assisting in customers’ development through our technology and service. This event showcased many new products and demonstrated our integrated capabilities across seven major areas: "optics (image capture/analysis), mechanical transmission, electric control (PLC), software (AOI + AI), service, distribution channels, branding." We look forward to collaborating with various parties for a win-win!

CCM’s contact: Willy Tsai, Sales Manager

Email: A961102@ccm3s.com

精湛光學科技

2024產品發表會

周毓誠總經理

篩選機

異檢機

送料機

光學檢測

人工智慧

自動X光檢測

扣件

五金零件

Ching Chan Optical Technology (CCM)

new product launch

GM Thomas Chou

sorting machine

inspection machine

feeding machine

AOI

AI

AXI

fastener

hardware component

德國杜塞道夫線材展

扣件

國際展會

惠達雜誌

匯達實業

外銷媒合

廣告刊登

螺絲五金

五金工具

緊固件

台灣扣件展

印度新德里螺絲展

越南河內螺絲展

墨西哥瓜達拉哈拉螺絲展

美國拉斯維加斯螺絲暨機械設備展

波蘭克拉科夫螺絲展

義大利米蘭螺絲展

德國司徒加特螺絲展

wire Dusseldorf

FASTENER FAIR INDIA

FASTENER FAIR VIETNAM

FASTENER FAIR MEXICO

FASTENER POLAND

FASTENER FAIR ITALY

FASTENER FAIR GLOBAL

READ NEXT

Industry Activities

2024-11-21

Subscribe