Industry Activities

New Product Added. Bi-Mirth Successfully Developed the “Turbo Drill Screw”

Add to my favorite

2021-09-13

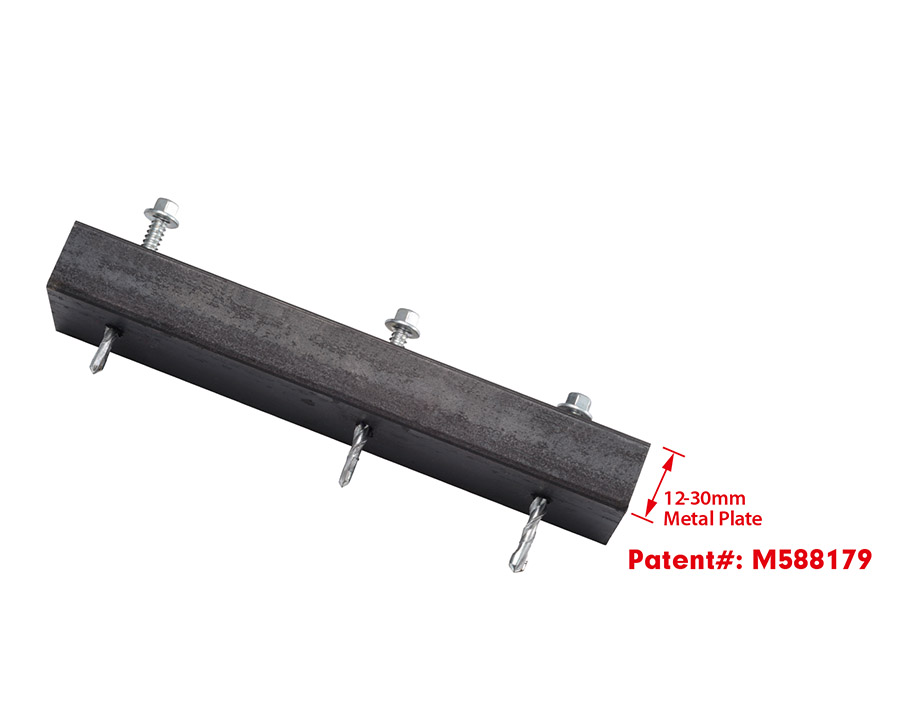

Successfully tapping into the high-end supply chains in Europe and the U.S. with quick drilling screws, drilling screws, self-tapping screws, and wood screws, Bi-Mirth Corp. has dedicated itself for years to the OEM production and R&D of various screws to meet customers’ urgent demands for high-quality, effective, and durable products. With relentless hard working of its professional R&D team, Bi-Mirth has once again successfully developed the new “Turbo Drill Screw” made of carbon steel, which can help achieve excellent fastening on thick steel plates.

Patented Structural Design;

Applicable to Thick Steel Plates

The main reason that this Turbo Drill Screw can help achieve excellent fastening on thick steel plates is the combination of two advantageous structural designs from drilling point and twisted thread. One advantage is the integration of a thinner drilling point to allow users accomplish a more efficient working performance. Another advantage is the integration of the twisted thread, which can help to overcome the high difficulty in drilling through a thick steel plate, to achieve an outstanding metal filings removal.

Bi-Mirth President Thomas Shih said, “Our R&D team spent almost 2 years developing this product and improving the die design to the almost perfect status. It would be absolutely no problem if a user takes this Turbo Drill Screw to fasten a thick steel plate in the thickness of 12mm to 30mm!”

Exceptional Results in Salt Spray and Kersternich Testing; Products are Not Susceptible to Hydrogen Embrittlement

In addition to great corrosion-resistant VG Coating, this Turbo Drill Screw can also pass 2,000-5,000 hours of salt spray and 20-50 cycles of Kesternich testing.

President Shih added, “We have world-leading technology to treat products well in terms of salt spray and Kersternich, and have maintained long-term collaboration with a well-known university in the segment of electroplating and heat treating. We even have our own electroplating and heat treating lines, so our products are almost not susceptible to hydrogen embrittlement.”

Certified and Patented in the EU and Taiwan

Bi-Mirth has all of its manufacturing lines compliant with CE, ISO, and ETA requirements and has introduced into its plants the state-of-the-art facilities from Germany as well as more than 100 sets of screw heading, drilling, thread rolling, thread cutting, and forming machines to respond to global customers’ demands.

President Shih said, “Thus far, this Turbo Drill Screw has been certified and patented in the EU and Taiwan, and several domestic and overseas customers have also demonstrated their high interest in purchasing this product. In the future we also plan to develop the Turbo Drill Screw in diameters of 8mm (5/16”) and 10mm (3/8”) to respond to more customers’ demands for outdoor engineered fastening products.”

Contact: Bi-Mirth Sales Dept.

Email: sales@bimirth.com.tw

Taiwan Bi-Mirth Corp

Turbo Drill Screw

fast drilling

台灣吉瞬

快鑽螺絲

厚鋼板

thick metal plate

扣件

國際展會

惠達雜誌

匯達實業

外銷媒合

廣告刊登

螺絲五金

五金工具

紧固件

台灣扣件展

印度新德里螺絲展

越南河內螺絲展

墨西哥瓜達拉哈拉螺絲展

美國拉斯維加斯螺絲暨機械設備展

波蘭克拉科夫螺絲展

義大利米蘭螺絲展

德國司徒加特螺絲展

wire Dusseldorf

FASTENER FAIR INDIA

FASTENER FAIR VIETNAM

FASTENER FAIR MEXICO

FASTENER POLAND

FASTENER FAIR ITALY

FASTENER FAIR GLOBAL

FASTENER WORLD